Key Takeaways:

- An air clutch system uses compressed air to engage and disengage the clutch for smooth gear shifting and power transfer in a vehicle’s transmission system.

- The mechanics behind an air clutch system rely on friction and pressure between the clutch plate and pressure plate, allowing for precise power transfer.

- Upgrading to an air clutch system can improve performance, power, durability, and control in a vehicle.

- When choosing an air clutch system, consider your vehicle’s specific needs and explore different options and features available.

- To maximize performance and longevity, follow proper installation procedures and perform regular maintenance, including inspections, checking air compressor pressure, monitoring the air reservoir, and following the manufacturer’s recommended schedule.

1. How does an Air Clutch System work?

An air clutch system is a vital component in a vehicle’s transmission system that allows for smooth gear shifting and power transfer. It utilizes compressed air to engage and disengage the clutch, providing a seamless connection between the engine and the transmission. Understanding the basics of an air clutch system and the mechanics behind it can help you appreciate its importance in enhancing your driving experience.

1.1 Understanding the basics of an Air Clutch System

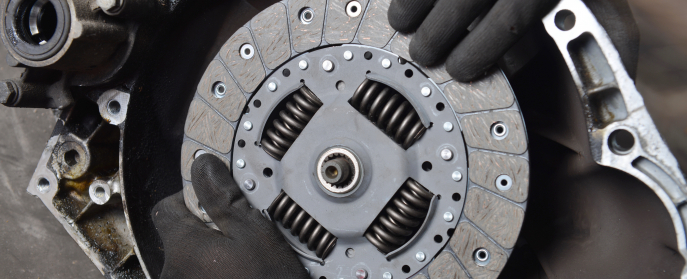

The primary function of an air clutch system is to enable the driver to control the power transfer from the engine to the transmission. It includes three main parts: the clutch plate, pressure plate, and release mechanism. The clutch plate attaches to the transmission shaft, and the pressure plate connects to the engine flywheel. Pressing the clutch pedal disengages the clutch, enabling smooth gear shifting. Releasing the pedal engages the clutch, transferring power from the engine to the wheels.

An air clutch system differs from traditional clutch systems as it uses compressed air instead of a hydraulic or cable mechanism. The compressed air is stored in a reservoir and is controlled by a valve. When the valve is activated, the compressed air is released, activating the clutch and allowing for gear engagement.

1.2 The mechanics behind the Air Clutch System

The mechanics of an air clutch system rely on the principles of friction and pressure. When the clutch pedal is pressed, it activates the release mechanism, which moves the pressure plate away from the clutch plate. This disengages the clutch, interrupting the power transfer from the engine to the transmission. When the clutch pedal is released, the release mechanism moves the pressure plate towards the clutch plate, creating pressure and friction between the two plates. This engagement allows power to be transmitted smoothly to the transmission, enabling seamless gear shifts and improved performance.

The use of compressed air in an air clutch system offers several advantages over traditional clutch systems. Compressed air provides consistent and reliable pressure, ensuring precise clutch engagement and disengagement. Additionally, air clutches are less prone to wear and tear, resulting in improved durability and longevity.

2. Benefits of upgrading to an Air Clutch System

Upgrading to an air clutch system can significantly enhance your vehicle’s performance and driving experience. It offers several benefits that make it a worthwhile investment for enthusiasts and professionals alike.

2.1 Improved performance and power

An air clutch system allows for faster gear shifts, reducing the time it takes for power to be transferred from the engine to the wheels. This results in quicker acceleration and improved overall performance. The precise control offered by an air clutch system also allows for better control over gear engagement, ensuring optimal power delivery.

Furthermore, an air clutch system can handle higher torque loads than traditional clutch systems, making it suitable for vehicles with upgraded engines or modified powertrain setups. It can handle the increased power output without sacrificing reliability or performance.

2.2 Enhanced durability and longevity

Compared to traditional clutch systems, air clutches are designed to withstand higher operating temperatures and are less prone to overheating. This makes them more durable and less susceptible to premature wear and tear.

The use of compressed air in an air clutch system eliminates the need for hydraulic fluids or cables, which can deteriorate over time and require frequent maintenance. The absence of these components reduces the risk of leaks and ensures consistent performance over a more extended period.

2.3 Superior control and accuracy

One of the key advantages of an air clutch system is the precise control it offers. The use of compressed air allows for rapid clutch engagement and disengagement, resulting in smooth gear shifts and precise power transfer. This level of control enhances the overall driving experience, especially in high-performance vehicles or situations that require quick gear changes.

Additionally, an air clutch system provides better modulation, allowing the driver to adjust the clutch engagement point to match their driving style and road conditions. This level of customization ensures optimal performance and control in various driving scenarios.

3. Choosing the right Air Clutch System for your vehicle

When selecting an air clutch system for your vehicle, it’s essential to consider its specific needs and requirements. Various factors should be taken into account to ensure compatibility and optimal performance.

3.1 Considering your vehicle’s specific needs

Before choosing an air clutch system, evaluate your vehicle’s powertrain setup, engine specifications, and intended use. Consider factors such as torque output, horsepower, and the vehicle’s weight. These considerations will help determine the appropriate size and type of air clutch system required to handle the demands of your vehicle.

If you have an upgraded engine or plan to make modifications to your vehicle’s powertrain, it’s crucial to choose an air clutch system that can handle the increased power output. An air clutch system designed for higher torque applications will ensure reliability and performance under these conditions.

3.2 Exploring different options and features

There are various manufacturers and models of air clutch systems available in the market, each offering unique features and capabilities. Research different options and compare their specifications, such as clutch plate size, pressure plate design, and actuation method.

Consider whether you require a single-disc or multi-disc clutch system, depending on your vehicle’s power requirements and intended use. Additionally, evaluate the ease of installation, maintenance requirements, and warranty offered by different manufacturers.

4. Installation and maintenance tips for your Air Clutch System

Proper installation and proactive maintenance are crucial for maximizing the performance and longevity of your air clutch system.

4.1 Step-by-step guide to installing an Air Clutch System

Installing an air clutch system requires technical expertise and knowledge of your vehicle’s transmission system. It’s recommended to consult a professional mechanic or follow the manufacturer’s installation instructions carefully.

The installation process generally involves removing the existing clutch system, including the clutch plate, pressure plate, and release mechanism. The air clutch system components, including the clutch plate, pressure plate, and actuation mechanism, are then installed according to the manufacturer’s specifications.

4.2 Proactive maintenance to maximize performance

Regular maintenance is essential to ensure that your air clutch system operates optimally and remains reliable over time. Here are some maintenance tips to keep in mind:

- Regularly inspect the air clutch system for signs of wear, such as worn clutch plates, damaged pressure plates, or leaking air lines. Replace any worn or damaged components promptly.

- Check the air compressor regularly to ensure it is generating sufficient pressure for proper clutch engagement. Clean or replace the air filter as necessary.

- Monitor the air reservoir for moisture buildup or contamination. Drain any accumulated moisture and replace the desiccant or drying cartridge as needed.

- Periodically inspect the actuation mechanism and adjust the clutch engagement point if necessary.

- Follow the manufacturer’s recommended maintenance schedule, including lubrication of moving parts and inspection of air lines and fittings.

By following these maintenance tips and addressing any issues promptly, you can maximize the performance and lifespan of your air clutch system, ensuring a smooth and reliable driving experience.

FAQ

Question: What is an air clutch system? – An air clutch system is a vital component in a vehicle’s transmission system that uses compressed air to engage and disengage the clutch for smooth gear shifting and power transfer.

Question: How does an air clutch system work? – An air clutch system utilizes compressed air to engage and disengage the clutch, providing a seamless connection between the engine and the transmission. When the clutch pedal is pressed, it disengages the clutch, allowing for smooth gear shifts. Releasing the pedal engages the clutch, transmitting power from the engine to the wheels.

Question: What are the benefits of upgrading to an air clutch system? – Upgrading to an air clutch system can improve performance, power, durability, and control in a vehicle. It allows for faster gear shifts, better power delivery, greater durability, and precise control over gear engagement.

Question: How do I choose the right air clutch system for my vehicle? – When choosing an air clutch system, consider your vehicle’s specific needs and requirements, such as torque output, horsepower, and weight. Additionally, explore different options and features offered by manufacturers, comparing specifications and considering ease of installation and maintenance requirements.

Question: What are some installation and maintenance tips for an air clutch system? – Proper installation and proactive maintenance are important for maximizing the performance and longevity of an air clutch system. Installation should be done by a professional or following the manufacturer’s instructions. Maintenance tips include regular inspections for wear, checking air compressor pressure, monitoring the air reservoir, and following the manufacturer’s recommended maintenance schedule.